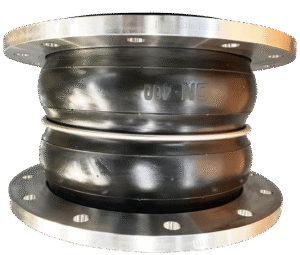

Rubber Expansion Joints

Flexible Connection · Vibration Control

Premium rubber expansion joint designed for pipeline flexibility and vibration absorption

✓ Superior flexibility & movement absorption ✓ Excellent vibration dampening ✓ Chemical resistant rubber compounds ✓ Reduces pipe stress & noise

Rubber Expansion Joints

Our comprehensive range of rubber expansion joints delivers superior vibration isolation and pipe movement accommodation for industrial applications.

Technical Specifications

| Available Sizes: | 15mm to 3000mm (DN15 to DN3000) |

| Available Lengths: | Standard length, 130mm, 152mm, 200mm, 260mm, 300mm, ect. |

| Rubber Materials: | EPDM, NBR, CR, NR, VITON, etc. |

| Flange Materials: | SS316, SS304, Carbon Steel, etc. |

| Flange Standards: | PN16, PN10, PN16, Table D, Table E, ANSI 150#, ANSI300#, etc. |

How are rubber expansion joints manufactured?

Factory production process and manufacturing techniques behind rubber expansion joints.

Manufacturing Excellence & Quality Assurance

Advanced materials sourcing, proprietary formulations, and precision manufacturing processes ensure superior product performance and longevity.

Vietnamese Raw Materials

Self-Developed Rubber Formula

Rubber Testing Report

Premium Rubber Properties

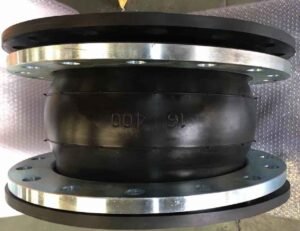

How to Identify Premium vs. Standard Rubber

✓ Premium Quality

- Appearance: Uniform matte finish

- Color: Deep, consistent black

- Odor: Minimal chemical smell

- Flexibility: Elastic, no cracking

- Surface: Smooth, no air bubbles

✗ Inferior Quality

- Appearance: Uneven, glossy surface

- Color: Faded or inconsistent

- Odor: Strong chemical/oil smell

- Flexibility: Stiff, prone to cracking

- Surface: Rough, visible defects

⚡ Our Advantage

- Formula: Proprietary blend

- Testing: SEAFAR test report

- Durability: 35% longer lifespan

- Performance: 2.5 MPa pressure rating

- Quality: Zero-defect guarantee

| Property | Our Standard | Industry Average | Certification |

|---|---|---|---|

| Pressure Resistance | 2.5 MPa | 1.6 MPa | ISO 1167 Certified |

| Service Life | 25+ Years | 15-18 Years | Accelerated Aging Test |

| Chemical Resistance | pH 2-12 | pH 4-10 | ROHS/REACH Compliant |

| Temperature Range | -40°C to +150°C | -20°C to +80°C | ASTM D2000 |

| Elasticity Retention | 95% after 10 years | 75% after 10 years | DIN 53505 Shore A |

Flange Options for Rubber Expansion Joints

The most commonly used are carbon steel flanges and stainless steel flanges, there are also a variety of flanges available for special environments.

Carbon Steel Flanges

Stainless Steel Flanges

Hot-dip Galvanized Flanges

Marine Vessels Flanges

Fire Protection Flanges

Customized Flanges

Quality Assurance & Control

6-Stage Quality Control Process

Raw Material Testing & Rubber Refining Standards

Comprehensive inspection of raw rubber compounds, additives, and materials with standardized refining processes to ensure chemical composition and physical property compliance.

Primary Processing & Winding Formation Standards

Standardized initial processing procedures and precision winding/forming operations with controlled parameters for consistent product shaping and dimensional accuracy.

Vulcanization Standards

Precise vulcanization process control with standardized temperature, pressure, and timing parameters to achieve optimal rubber curing and cross-linking properties.

Assembly & Labeling Standards

Standardized assembly procedures with precise component integration and accurate labeling protocols ensuring proper identification and traceability requirements.

Packaging Standards

Comprehensive packaging protocols with protective material specifications, sealing procedures, and quality verification to ensure product integrity during transportation.

Storage Standards

Standardized storage conditions with controlled environment parameters, inventory management systems, and preservation protocols to maintain product quality over time.

Our Quality Commitment

Free Replacement Guarantee

Any quality-related issues during the warranty period will be resolved with free product replacement at no additional cost to you.

Shipping Cost Included

All replacement products include full shipping costs covered by GYLDT, ensuring complete customer satisfaction without hidden expenses.

"Quality is not just our standard – it's our commitment to you."

Supply Chain Excellence

From production to your doorstep - we ensure reliable, efficient delivery with comprehensive logistics support

Rapid Supply Capability

Standard Models

3 days delivery from extensive inventory stock

Custom Solutions

7-10 days for non-standard specifications

Abundant Raw Material Reserves

Sufficient inventory to ensure continuous production

Free Professional Packaging

Express delivery to port next day | Domestic courier to any China port within 3 days

Support multiple modes of transportation

Express Port Delivery

We partner with international express and freight companies for 10+ years, ensuring reliable global shipping solutions.

Trusted Freight Partners

Material Selection Guide - Rubber Material Comparison

Choosing the right material is crucial for optimal product performance. Comprehensive analysis of rubber materials for optimal valve performance across different applications

EPDM

Ethylene Propylene Diene Monomer

Suitable Media

- • Water & steam

- • Ozone & UV exposure

- • Acids & alkalis

- • Polar solvents

Primary Applications

Wastewater treatment, marine environments, HVAC systems, outdoor installations

NR

Natural Rubber

Suitable Media

- • Fresh water

- • Non-petroleum fluids

- • Low-temperature applications

- • General purpose sealing

Primary Applications

General industrial valves, low-temperature systems, cost-effective solutions

NBR

Nitrile Butadiene Rubber

Suitable Media

- • Petroleum oils

- • Hydraulic fluids

- • Fuel systems

- • Mineral oils

Primary Applications

Oil & gas industry, hydraulic systems, fuel handling, automotive applications

FKM/Viton

Fluoroelastomer

Suitable Media

- • Aggressive chemicals

- • High-temperature fluids

- • Acids & solvents

- • Steam & hot gases

Primary Applications

Chemical processing, high-temperature systems, aerospace, pharmaceutical

IIR

Butyl Rubber

Suitable Media

- • Hot water & steam

- • Polar solvents

- • Oxygenated compounds

- • Gas applications

Primary Applications

Gas sealing, steam systems, pharmaceutical, food processing

CR

Neoprene (Chloroprene)

Suitable Media

- • Moderate oils

- • Refrigerants

- • Weather exposure

- • Ozone resistance

Primary Applications

Marine applications, refrigeration, moderate chemical exposure, general purpose

Performance Matrix

Comparative analysis of key properties

| Material | Oil Resistance | Weather Resistance | Chemical Resistance | Temperature Range | Cost Efficiency |

|---|---|---|---|---|---|

| EPDM | |||||

| NR | |||||

| NBR | |||||

| FKM/Viton | |||||

| Butyl (IIR) | |||||

| Neoprene (CR) |

Selection Guidelines

Water Treatment

EPDM recommended for superior chemical resistance and longevity in wastewater applications.

Primary Choice: EPDMOil & Gas

NBR or FKM/Viton for petroleum products and high-temperature hydrocarbon applications.

Primary Choice: NBR/FKMChemical Processing

FKM/Viton essential for aggressive chemicals and high-temperature chemical environments.

Primary Choice: FKMIndustrial Application Cases

Real-world implementations of our duckbill check valves across various industrial sectors, showcasing proven performance and reliability.

Thermal Power Plant Cooling System

Installed in a 600MW coal-fired power plant's circulating water system. Our EPDM duckbill valves have been operating continuously for 5 years without replacement, handling 15,000 m³/h flow rate in harsh thermal conditions.

Chemical Plant Acid-Resistant Pipeline

Deployed in a sulfuric acid production facility using VITON rubber valves. Successfully handling pH 1-2 acidic media at temperatures up to 80°C, demonstrating exceptional chemical resistance and durability.

Marine Vessel Seawater Pump Room

Installed aboard a 50,000-ton cargo vessel's ballast water system. Our neoprene duckbill valves provide reliable backflow prevention in seawater applications, withstanding constant saltwater exposure and pressure variations.

Municipal Wastewater Treatment Plant

Serving a 500,000-population city's main treatment facility. EPDM duckbill valves in the final discharge system prevent tidal backflow, ensuring consistent outfall performance while reducing maintenance costs by 60%.

Dairy Processing Facility

Implemented in a major dairy plant's CIP (Clean-in-Place) system. Food-grade EPDM valves ensure hygienic operations while preventing cross-contamination between different product lines during cleaning cycles.

Copper Mine Dewatering System

Operating in an open-pit copper mine's water management system. Heavy-duty nitrile rubber valves handle abrasive slurries and extreme temperature variations, maintaining operational efficiency in challenging mining conditions.

Send Us a Message

Get custom valve solutions from our expert team