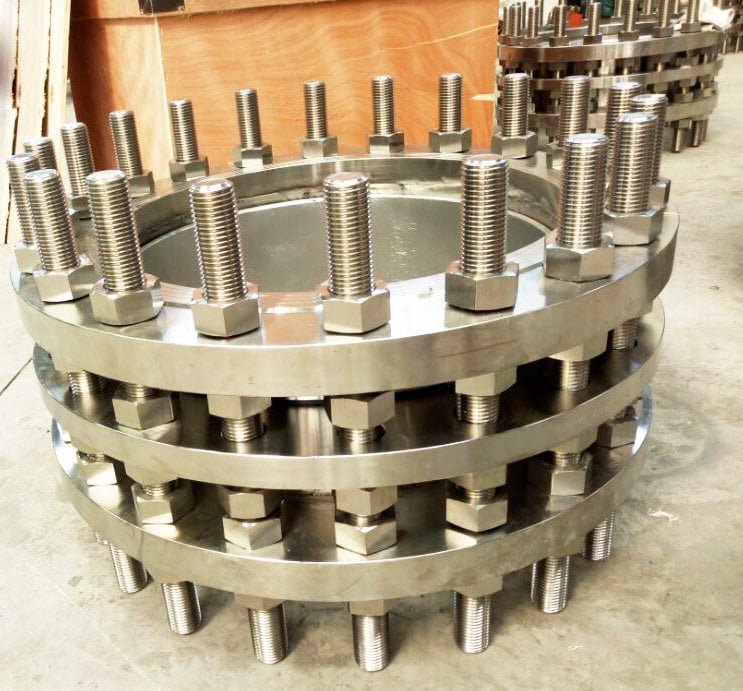

Stainless Steel Dismantling Joint

High-performance flexible coupling designed for easy pipe maintenance and system expansion. Manufactured with precision engineering for industrial and municipal applications.

Key Features & Benefits

Engineered for reliability, built for performance. Our dismantling joints deliver superior functionality across demanding applications.

Easy Installation

Quick and simple installation process with standard flanged connections. Reduces downtime and labor costs.

Corrosion Resistant

Premium SS304/SS316 stainless steel construction ensures long-lasting performance in harsh environments.

Flexible Design

Accommodates pipe movement, thermal expansion, and minor misalignment while maintaining system integrity.

Custom Standards

Available in ANSI, DIN, JIS, and BS standards. Custom dimensions and materials available upon request.

Pressure Rated

Tested and rated for high-pressure applications up to 16 bar (232 psi) with safety factor compliance.

Quality Certified

ISO 9001 certified manufacturing with CE marking. Full material traceability and test certificates provided.

Product Gallery

Detailed views of our precision-engineered dismantling joints

Front Assembly View

Complete unit with flanges

Side Profile

Flexible coupling design

Installation Example

Typical piping application

Technical Specifications

Comprehensive technical data and performance parameters

General Specifications

Standards Compliance

Performance Features

- Axial compression and extension capability

- Angular and lateral deflection absorption

- Vibration and noise reduction

- Easy valve and equipment maintenance

- Thermal expansion compensation

Applications

Ready to Order?

Get a custom quote for your specific requirements. Our engineering team is ready to assist with sizing, material selection, and technical specifications.