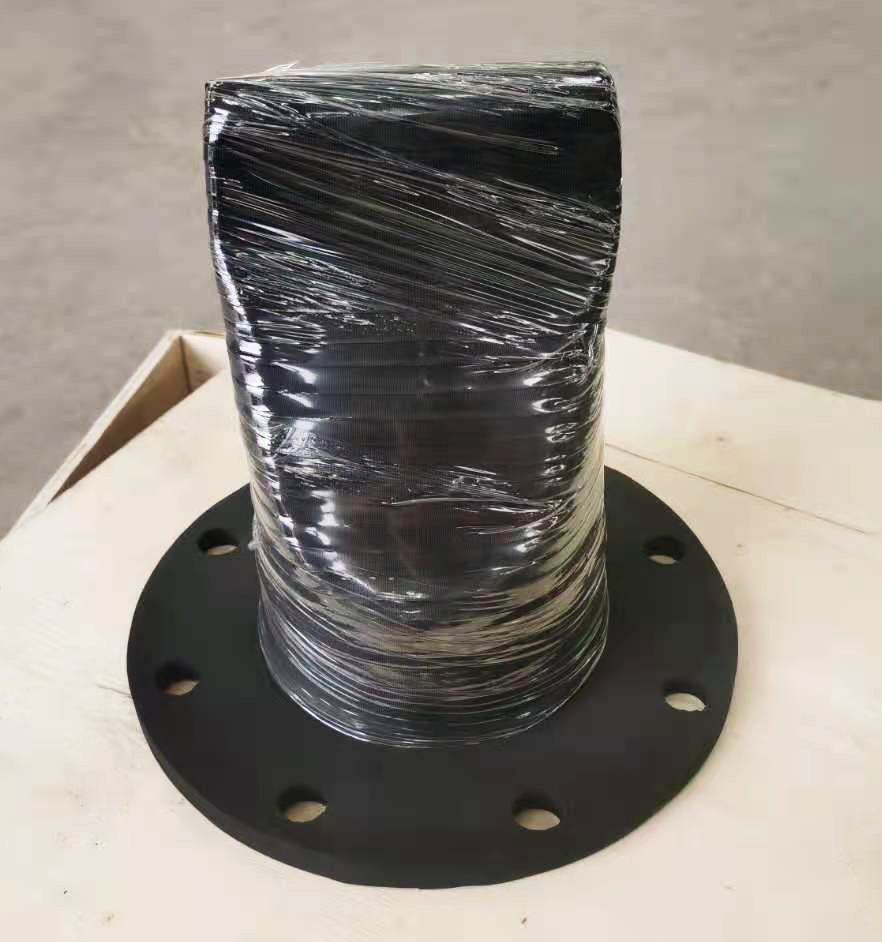

Inline Flanged Duckbill Check Valve

Professional inline flanged duckbill check valve designed for superior backflow prevention in demanding industrial applications. Features robust construction with customizable specifications.

Technical Specifications

Engineered for excellence with premium materials and precise manufacturing standards

Product Details

Key Advantages

Excellent Backflow Prevention

Unique duckbill design ensures complete seal against reverse flow

Low Cracking Pressure

Opens with minimal forward pressure for efficient operation

Self-Cleaning Design

Non-clogging operation with automatic debris clearance

Long Service Life

Durable materials ensure years of reliable operation

When to Use Inline Flanged Duckbill Check Valves

These specialized valves are essential in critical applications where backflow prevention and reliable operation are paramount

Wastewater Treatment Plants

Perfect for preventing backflow in sewage discharge systems, especially where gravity flow meets pressurized systems. Essential for maintaining treatment process integrity.

Stormwater Management

Critical for storm drainage systems where tidal influence or surging water levels could cause damaging backflow into collection networks.

Industrial Process Lines

Ideal for chemical processing, food production, and manufacturing where product contamination from backflow must be absolutely prevented.

Marine & Coastal Applications

Essential for outfalls and discharge points where tidal action, wave surge, or varying water levels create backflow risks.

Power Plant Cooling Systems

Critical for thermal power plants where cooling water discharge must prevent backflow that could damage expensive equipment or disrupt operations.

Gravity Flow Systems

Perfect for applications where maintaining unidirectional flow is critical, such as sump pump discharge lines and gravity drainage networks.

Expert Recommendation

Inline flanged duckbill check valves are particularly recommended for applications where space constraints require the valve body to be installed within the pipe system, while still providing the superior backflow prevention characteristics of traditional duckbill technology. The flanged connection ensures secure, leak-proof installation suitable for higher pressure applications.

Installation Guide & Important Considerations

Proper installation is crucial for optimal performance and longevity of your inline flanged duckbill check valve

Step-by-Step Installation

Pre-Installation Inspection

Verify valve size matches pipe diameter. Inspect duckbill rubber for any damage or defects. Ensure flange bolt holes align with mating flanges.

Pipe Preparation

Clean pipe ends thoroughly. Remove any debris, scale, or rough edges that could damage the valve. Ensure pipe alignment is straight and true.

Gasket Installation

Install appropriate gaskets between flanges. Use gasket material compatible with your media (EPDM, NBR, etc.). Ensure gaskets are properly centered.

Valve Positioning

Position valve with duckbill opening facing downstream (flow direction). Ensure valve body is properly oriented within the pipe bore.

Flange Connection

Insert bolts and tighten in a star pattern to ensure even pressure distribution. Use specified torque values for your flange standard and size.

Final Testing

Conduct pressure test to verify seal integrity. Test valve operation with forward and reverse flow conditions to confirm proper function.

Critical Installation Considerations

⚠️ Critical Warnings

- • Never install valve backwards - duckbill must face downstream

- • Do not exceed maximum working pressure specifications

- • Avoid sharp objects that could puncture the rubber duckbill

- • Do not use petroleum-based lubricants on rubber components

✓ Best Practices

- • Install in accessible location for future maintenance

- • Use stainless steel bolts in corrosive environments

- • Allow adequate clearance around valve for inspection

- • Document installation date and specifications for maintenance records

Environmental Factors

- • Consider temperature extremes when selecting rubber material

- • Account for chemical compatibility with process media

- • Protect from UV exposure in outdoor installations

- • Plan for thermal expansion in long pipe runs

Maintenance Schedule

- • Monthly: Visual inspection for external damage

- • Quarterly: Check flange bolt torque

- • Annually: Comprehensive inspection and function test

- • As needed: Replace if rubber shows signs of deterioration

Required Tools & Materials

Installation Tools

- • Torque wrench (calibrated to flange specifications)

- • Socket set and spanners

- • Pipe alignment tools

- • Cleaning equipment and solvents

- • Pressure testing equipment

Additional Materials

- • Compatible gasket material

- • Stainless steel bolts and nuts

- • Thread sealant (if required)

- • Anti-seize compound

- • Marking materials for documentation

Ready to Order Your Inline Flanged Duckbill Check Valve?

Get expert consultation and custom specifications tailored to your specific application requirements