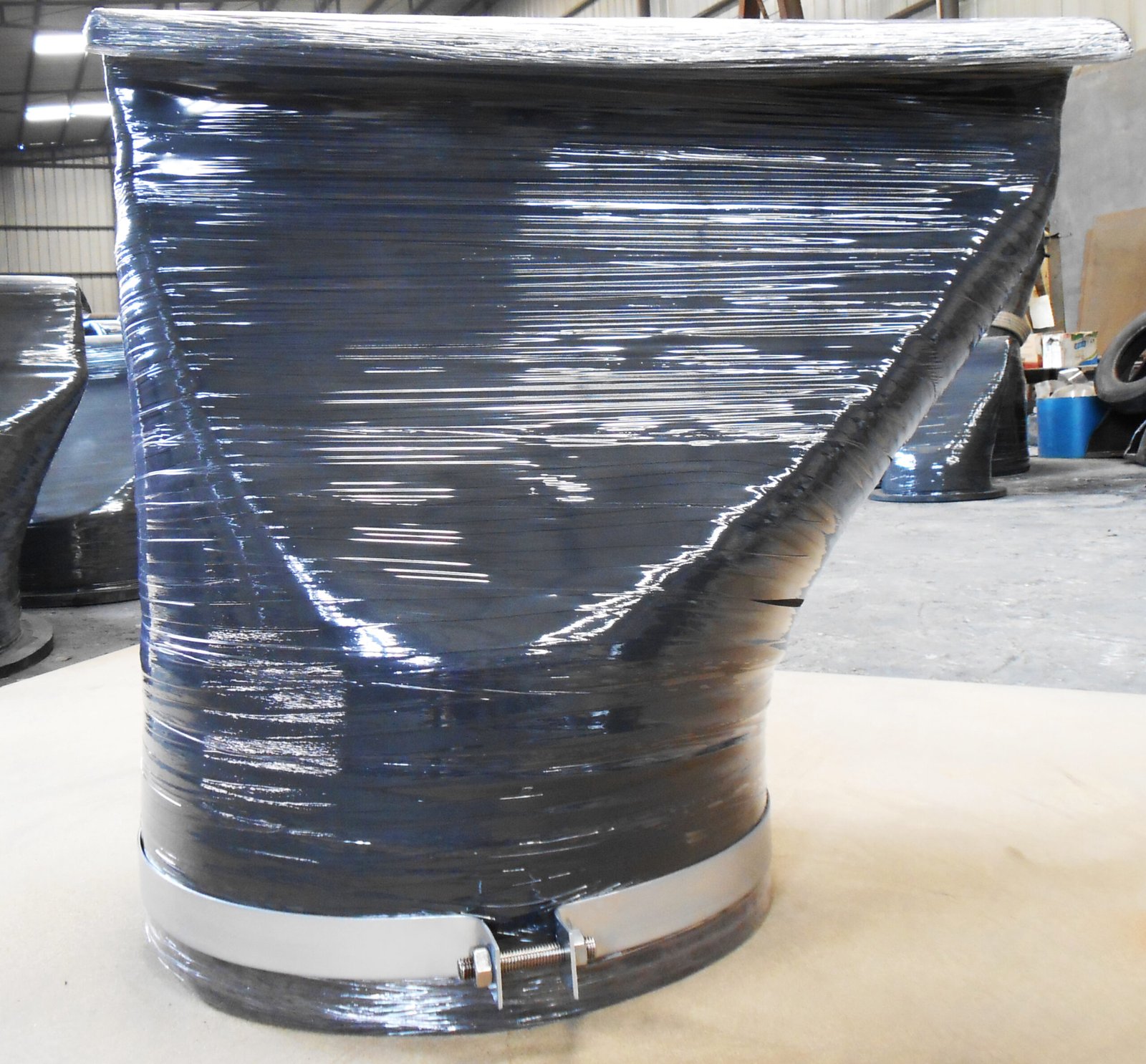

The Flat Bottom Duckbill Check Valve represents the pinnacle of backflow prevention technology. Our patented flat bottom design creates an enhanced sealing surface that ensures complete closure under all operating conditions.

Manufactured using premium elastomers and precision molding techniques, these valves deliver unmatched reliability in the most demanding industrial environments. The unique flat bottom configuration eliminates the common failure points found in traditional duckbill designs.

Each valve undergoes rigorous quality testing including pressure cycling, temperature resistance, and chemical compatibility verification to ensure decades of trouble-free operation.