Duckbill Check Valves

Backflow Prevention · Maintenance Free

High-performance duckbill check valve, manufactured with advanced technology

✓ Excellent sealing performance ✓ Corrosion-resistant materials ✓ Long-lasting durability ✓ Easy installation

Duckbill Check Valves

Discover our comprehensive range of duckbill check valves designed for superior backflow prevention and reliable performance in various applications.

Technical Specifications

| Available Sizes | 20mm to 3000mm (DN20 to DN3000) |

| Rubber Material | EPDM, NBR, CR, NR, VITON, etc. |

| Flange Material | SS316, SS304, Carbon Steel, etc. |

| Flange Standards | PN16, PN10, PN16, Table D, Table E, ANSI 150#, ANSI300#, etc. |

How to choose the right duckbill check valve?

Select the product according to the location of the product in the pipeline.

For installations at the end of discharge pipes

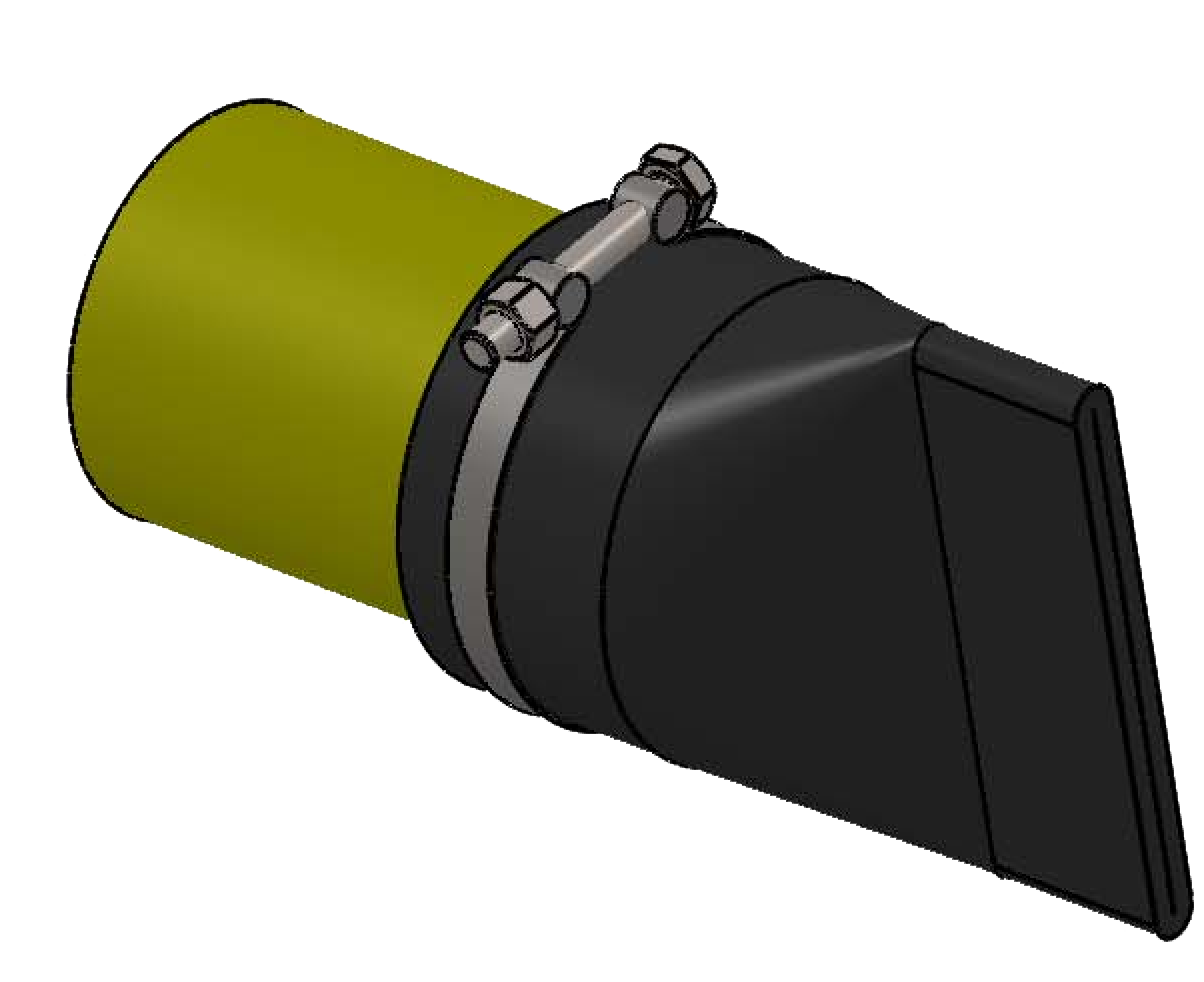

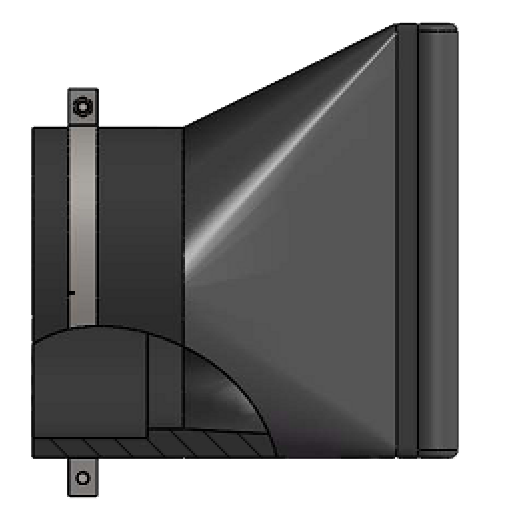

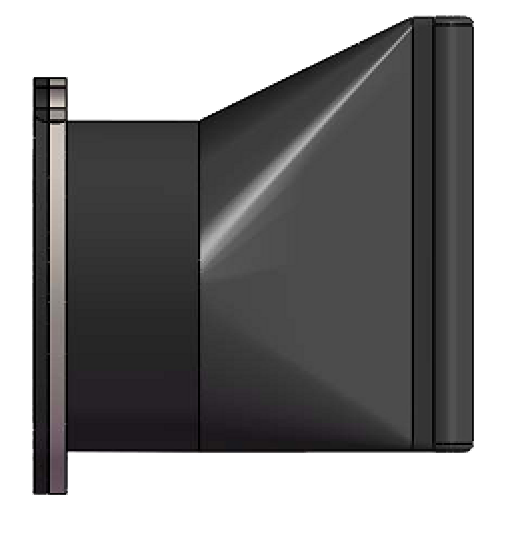

Clamp Type

Easy installation with clamp connection

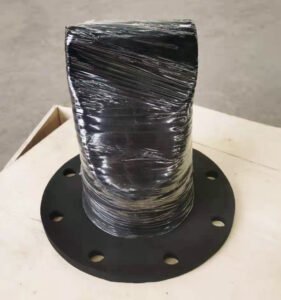

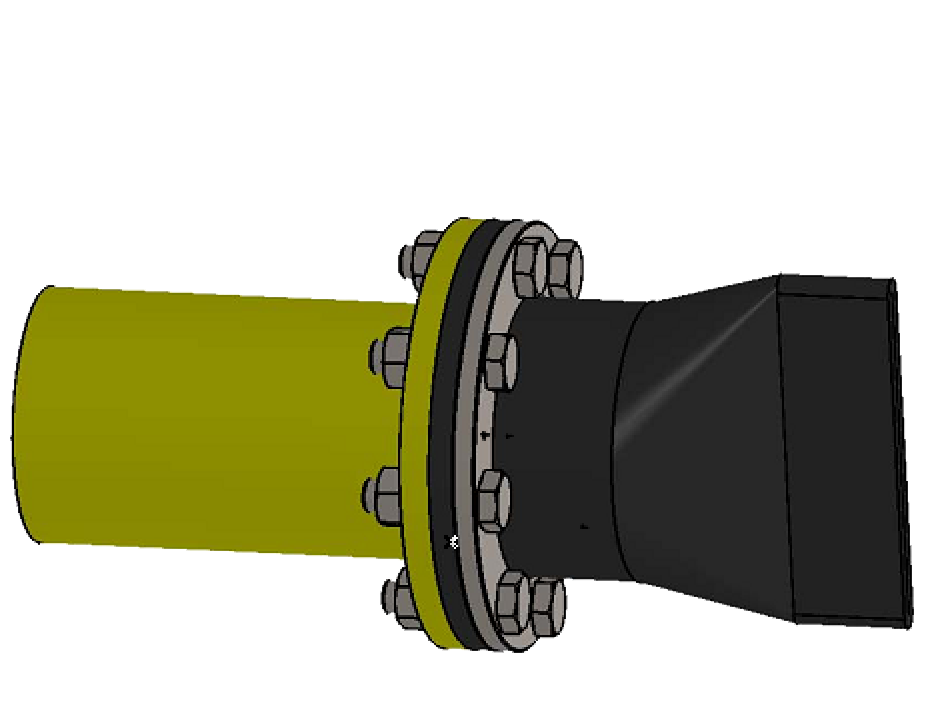

Flanged Type

Secure flanged connection for permanent installation

For installations inside existing pipe systems

Internal Clamp Type

Insert into existing pipe with clamp connection

Internal Flanged Type

Flanged connection within pipe system

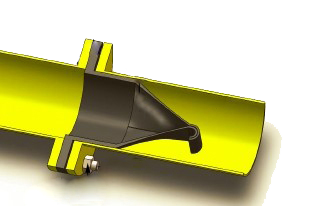

Flat Bottom Clamp

Low profile clamp design

Flat Bottom Flanged

Low profile flanged design

Key Selection Factors

Installation Method

Consider pipe end vs. in-line installation requirements

Connection Type

Choose between clamp or flanged connections based on pressure and permanence

Application Environment

Consider pressure ratings, flow rates, and environmental conditions

Connection Type Comparison

| Type | Application Scenarios | Structure/Connection Method | Advantages | Disadvantages |

|---|---|---|---|---|

| Clamp Type | Plastic pipe terminals (PVC/HDPE) Hose connections Steel pipe terminal + sleeve Space-limited applications Low-pressure systems | Flanged valve body + metal/plastic clamp secured to smooth pipe end |

✓

Rapid installation

✓

Low cost

✓

Lightweight

✓

Hose-compatible

|

×

Limited pressure rating (≤0.6 MPa)

×

Clamp quality critical

×

Requires straight pipe end

|

| Flange Type | Steel/ductile iron pipelines Pressure lines (pump discharge) High-pressure applications Large diameters (DN≥200) Mid-pipe check valve | Prefabricated standard flange (GB/DIN/ANSI) Bolted connection to pipeline flange |

✓

High pressure capacity (1.6MPa)

✓

Reliable sealing

✓

Universal application

✓

Robust

|

×

Complex installation (bolt alignment)

×

Higher cost (paired flanges)

×

Heavy weight

|

| Internal Clamp | Embedded concrete structures (manholes/tank walls/floors) Submerged outlets Flush wall requirements | Internal installation Valve inserted into opening Secured with internal clamps/bolts |

✓

External flush surface

✓

Ideal for submerged conditions

✓

Space-efficient

|

×

Internal access required

×

Seal dependent on wall treatment

×

Difficult maintenance

|

| Internal Flange | Embedded concrete structures (same as left) Higher pressure/larger valve applications | Flanged valve body Through-wall bolts Secured from inside wall surface |

✓

Max. strength (2.5MPa)

✓

Superior sealing (gasket+flange)

✓

External flush surface

|

×

Most complex installation

×

Mandatory internal access

×

Precise opening required

|

| Flat Bottom Type | Sump/pump pit bottoms Grade-level discharge points No vertical pipe/wall applications | Base plate flange Anchored with expansion bolts Directly to horizontal surface (concrete/steel) |

✓

No pipe/wall required

✓

Flexible positioning

|

×

Prone to sediment buildup

×

Requires level foundation

×

Bolts need corrosion protection

|

Industrial Applications

Duckbill check valves are widely applied across various industrial sectors, providing reliable fluid control solutions for different industries.

Water Treatment

Chemical Industry

Food Processing

Pharmaceutical

Marine Industry

Send Us a Message

Get custom valve solutions from our expert team