Customized Rubber Expansion Joint

Premium quality rubber expansion joints engineered with our unique formula developed from over 30 years of practice. Delivering superior shock absorption and expansion performance that outperforms industry standards.

Why Choose Our Expansion Joints

Superior performance backed by decades of engineering expertise, innovative materials, and precision manufacturing

Premium Materials

EPDM, neoprene, nitrile, NR, and VITON rubber options with superior elastomer performance and chemical resistance.

Customizable Design

Different lengths, shapes, flanges (SS316/SS304/Carbon Steel), and international standards available for your specific needs.

Superior Performance

Enhanced shock absorption and expansion effects with our unique formula, outperforming similar products in the market.

Quality Assurance

ISO9001-2000 certified with standardized processes and high yield rates ensuring consistent quality and reliability.

Fast Delivery

Large inventory and sufficient mold reserves ensure short delivery times for both standard and custom products worldwide.

Global Standards

American, Australian, British, and Japanese flange standards available to meet international project requirements.

Product Gallery

Explore our comprehensive range of rubber expansion joint configurations and types

Single Sphere

Ideal for basic expansion and contraction requirements in standard piping systems

Double Arch

Enhanced flexibility for complex piping systems with multiple movement requirements

Wide Arch

Maximum movement capability for demanding applications with extreme conditions

VITON Rubber

Superior chemical resistance for harsh environments and aggressive media

PTFE Lined

Superior chemical resistance and non-stick properties for critical applications

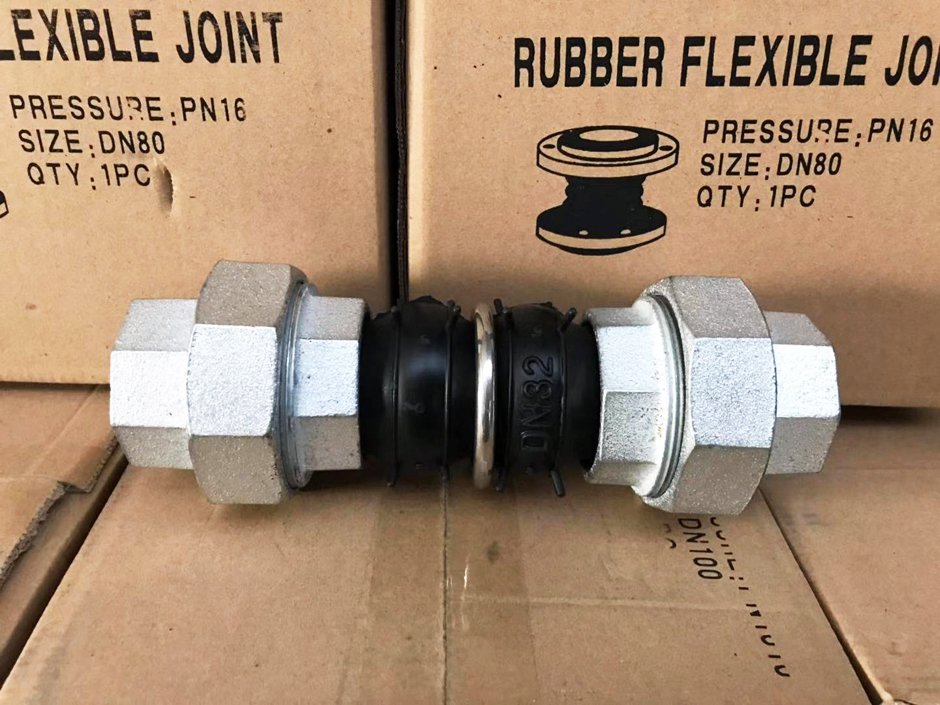

Threaded Union

Easy installation for smaller diameter applications and retrofit projects

Technical Specifications

Detailed specifications and precision manufacturing process for optimal performance

Materials & Standards

Rubber Materials

- EPDM (Ethylene Propylene Diene Monomer)

- Neoprene Rubber

- Nitrile Rubber (NBR)

- Natural Rubber (NR)

- VITON (Fluoroelastomer)

Flange Materials

- Stainless Steel 316 (SS316)

- Stainless Steel 304 (SS304)

- Carbon Steel

International Standards

- American Standard (ANSI/ASME)

- Australian Standard (AS)

- British Standard (BS)

- Japanese Standard (JIS)

Manufacturing Process

Rubber Refining

Unique formula development and rubber compound preparation using proprietary techniques

Sheet Making

Precision rubber sheet formation with consistent thickness and material properties

Winding Molding

Automated molding process for consistent shape formation and dimensional accuracy

Vulcanization

High-temperature curing process for optimal material properties and durability

Flange Assembly

Precision flange attachment and comprehensive final quality inspection

Quality Advantages

- High yield rate production ensuring consistency

- Large inventory capacity for immediate delivery

- Short delivery times worldwide

- Sufficient mold reserves for custom orders

- Custom logo and branding capability

Applications

Trusted by industries worldwide for critical piping systems and infrastructure projects

Wastewater Treatment

Treatment plants, discharge systems, and stormwater management

Power Plants

Thermal power plant cooling towers and steam systems

HVAC Systems

Commercial and industrial HVAC applications

Municipal Water

Water distribution, treatment, and supply systems

Ready to Get Started?

Contact our engineering team for custom solutions tailored to your specific requirements. With over 30 years of experience, we deliver premium quality products to 46+ countries worldwide.