Customized Duckbill Check Valve

Premium quality duckbill check valves engineered with patented technology and over 30 years of expertise. Delivering reliable backflow prevention with superior performance and zero maintenance requirements.

Why Choose Our Duckbill Valves

Superior performance backed by patented technology, innovative materials, and precision manufacturing

Patented Technology

Among the first in China to introduce duckbill valve technology with R&D patents for standard and curved-bill designs.

Zero Maintenance

Simple design with no moving parts eliminates maintenance requirements and provides reliable long-term operation.

Low Cracking Pressure

Opens at minimal pressure differential while providing excellent backflow prevention and self-cleaning properties.

Premium Materials

EPDM, neoprene, nitrile, and NR rubber options with SS316/SS304 flanges meeting international standards.

Corrosion Resistant

Superior resistance to corrosion and abrasion with quiet operation and lightweight design for easy installation.

Custom Solutions

Multiple installation types and international flange standards available to meet specific project requirements.

Duckbill Valve Types

Comprehensive range of duckbill check valve configurations for every application

Slip On Type

Installed outside pipe with clamp for easy retrofitting

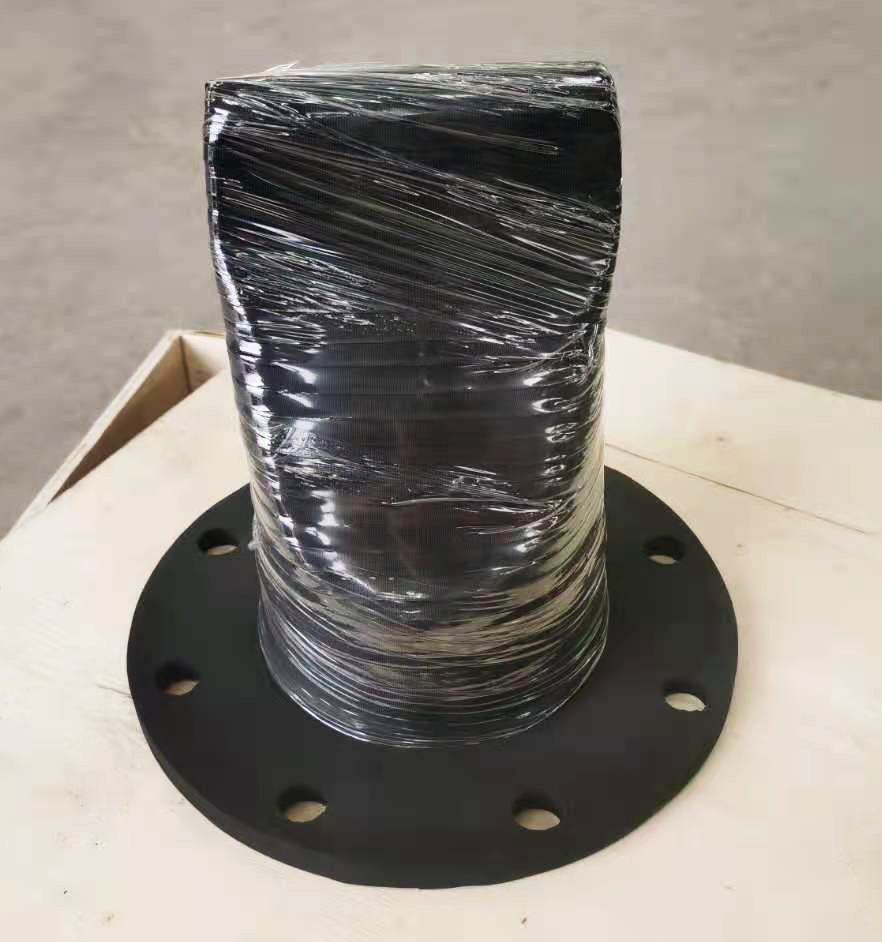

Flanged Type

Fixed at pipe end with flange for permanent installation

Insertable Type

Fixed inside pipe with clamp for internal mounting

Inline Flanged

Valve body installed inside pipe with flange connection

Technical Specifications

Detailed specifications and working principles for optimal performance

Materials & Standards

Rubber Materials

- EPDM (Ethylene Propylene Diene Monomer)

- Neoprene Rubber

- Nitrile Rubber (NBR)

- Natural Rubber (NR)

Flange Materials

- Stainless Steel 316 (SS316)

- Stainless Steel 304 (SS304)

- Carbon Steel

International Standards

- American Standard (ANSI/ASME)

- Australian Standard (AS)

- British Standard (BS)

- Japanese Standard (JIS)

Working Principle

Forward Flow

Duck bill opens with minimal pressure differential allowing fluid to flow freely through the valve

Backflow Prevention

Reverse pressure causes the bill to close tightly, preventing any backflow or contamination

Self-Cleaning

Flexible rubber construction prevents clogging and provides automatic cleaning action

Long Service Life

No moving parts eliminate wear and maintenance requirements for extended operation

Key Advantages

- Simplicity and reliability with no mechanical parts

- Excellent backflow prevention capabilities

- Low cracking pressure for efficient operation

- Non-clogging and self-cleaning properties

- Lightweight and compact design

Applications

Trusted by industries worldwide for critical backflow prevention and one-way flow control

Wastewater & Stormwater

Treatment plants, discharge systems, and stormwater management

Flood Control

Coastal defense and tidal control applications

Marine & Waterfront

Marine applications and waterfront protection systems

Industrial Processes

Chemical processing and industrial piping systems

Ready to Get Started?

Contact our engineering team for custom duckbill valve solutions tailored to your specific requirements. With patented technology and over 30 years of experience, we deliver reliable backflow prevention worldwide.